Why We Use 3D AOI and What It Does to Ensure Quality

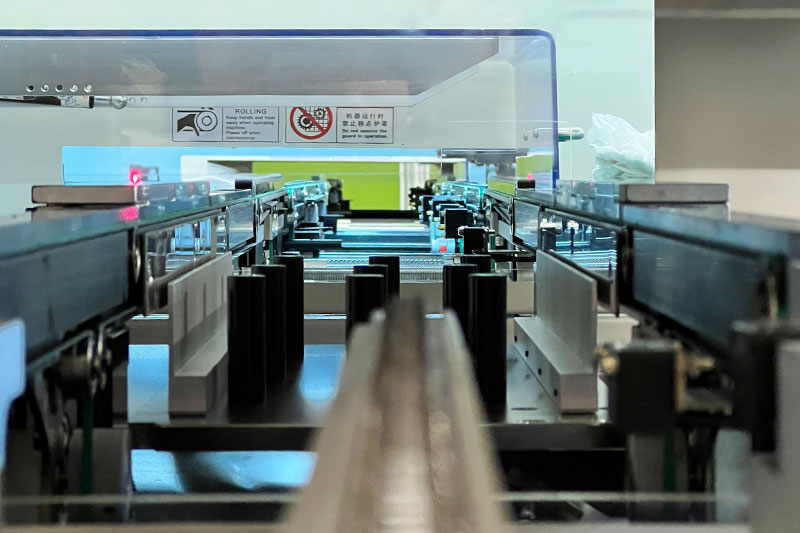

In the world of electronic manufacturing, maintaining high standards of quality and efficiency is paramount. At DSL, we leverage cutting-edge technologies to achieve this, and one such technology is 3D Automated Optical Inspection (AOI). This advanced system plays a crucial role in ensuring that every product leaving our facility meets the highest standards of quality.

Quality and Innovation

Customised Solutions

Reliable Communication

Why We Use 3D AOI in Electronic Manufacturing

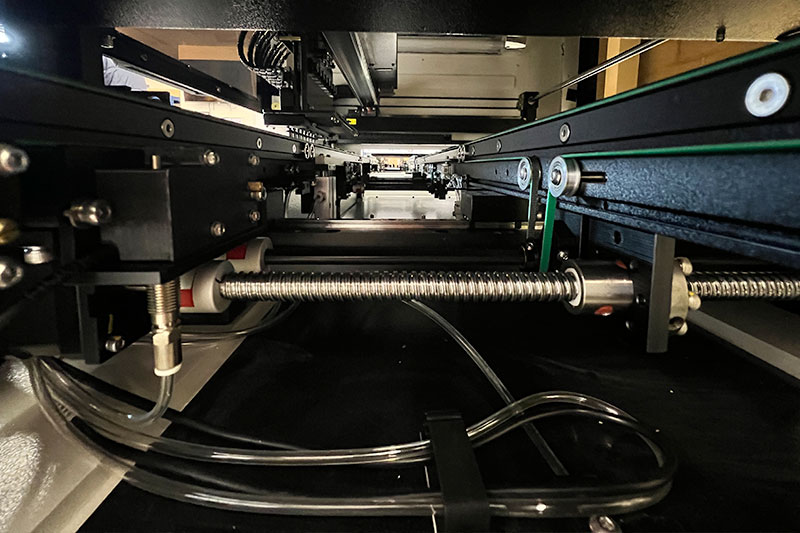

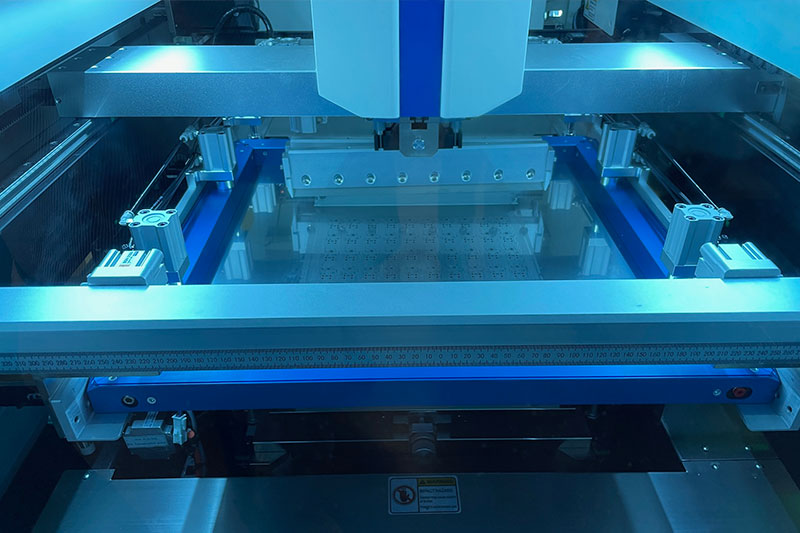

The complexity of modern PCB assemblies demands meticulous attention to detail. Traditional 2D AOI systems, while effective, have their limitations. They can detect surface-level defects, but they may miss issues related to component height and volume, which are critical for the functionality of advanced electronics. This is where 3D AOI steps in.

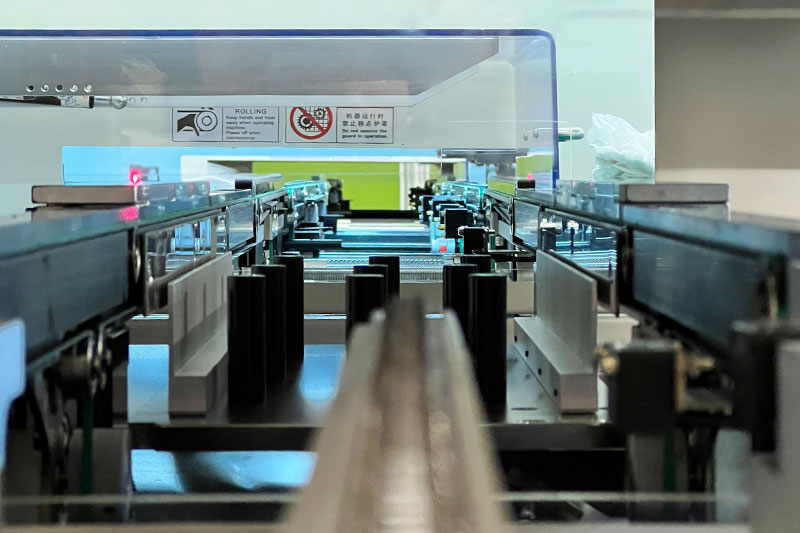

3D AOI utilises sophisticated imaging techniques to create a detailed three-dimensional representation of each PCB. This allows us to inspect not just the X and Y dimensions, but also the Z dimension — capturing height, shape, and volume of components with unparalleled accuracy. By integrating 3D AOI into our production line, we significantly enhance our ability to detect and correct defects at an early stage, preventing costly errors down the line.

Contact us today

Speak to one of our knowledgeable and experienced team.

What 3D AOI Does to Ensure Quality

1. Comprehensive Inspection: 3D AOI examines every aspect of the PCB assembly, from component placement to solder joint quality. It measures the height and volume of solder joints, ensuring they meet stringent industry standards. This comprehensive inspection capability allows us to identify and rectify issues that might be overlooked by 2D systems.

2. Early Defect Detection: By providing a detailed view of each component and its placement, 3D AOI enables early detection of potential defects. This early intervention is crucial in preventing defects from propagating through the production process, which can save significant time and resources.

3. Enhanced Precision: The precision of 3D AOI ensures that even the smallest defects are detected. Whether it’s a slight misalignment of a component or an insufficient solder joint, 3D AOI’s high-resolution imaging makes it possible to catch these issues before they affect the performance of the final product.

4. Data-Driven Improvements: 3D AOI systems generate a wealth of data that can be analysed to identify trends and recurring issues. This data-driven approach allows us to continuously refine our processes, enhancing overall production quality and efficiency.

5. Compliance and Reliability: Ensuring that every PCB meets regulatory standards and performs reliably is non-negotiable. 3D AOI helps us achieve this by providing a thorough inspection that guarantees compliance with industry standards and enhances the reliability of our products.

3. Enhanced Precision: The precision of 3D AOI ensures that even the smallest defects are detected. Whether it’s a slight misalignment of a component or an insufficient solder joint, 3D AOI’s high-resolution imaging makes it possible to catch these issues before they affect the performance of the final product.

4. Data-Driven Improvements: 3D AOI systems generate a wealth of data that can be analysed to identify trends and recurring issues. This data-driven approach allows us to continuously refine our processes, enhancing overall production quality and efficiency.

5. Compliance and Reliability: Ensuring that every PCB meets regulatory standards and performs reliably is non-negotiable. 3D AOI helps us achieve this by providing a thorough inspection that guarantees compliance with industry standards and enhances the reliability of our products.

At DSL, we believe that the fusion of technological excellence and human expertise is the cornerstone of producing top-tier electronic assemblies. Our investment in 3D AOI technology is a testament to our commitment to quality. By combining state-of-the-art machinery with the meticulous skills of our operators, we ensure that every product we manufacture not only meets but exceeds the expectations of our clients.

Why Work with DSL to Manufacture

For over 30 years, DSL has been delivering dependable PCB assemblies, backed by an unparalleled 5-year guarantee. Our commitment to the highest quality standards sets us apart in the industry.

Our in-house design engineering team is always on hand to provide expert advice on design optimisations, ensuring your products are not only functional but also efficient and cost-effective. Coupled with our flexible delivery service, which allows you to pay for the product only as required, we ensure that you receive your assemblies exactly when you need them, reducing waste and enhancing efficiency.

Choosing DSL means choosing a partner dedicated to excellence, innovation, and reliability. Our extensive experience and unwavering commitment to quality assurance ensure that your products are built to the highest standards, giving you peace of mind and a competitive edge in the market. With DSL, you are not just getting a service provider; you are gaining a trusted partner invested in your success.