Manufacturing Process

Ensuring Excellence in Every PCB Assembly

DSL’s robust manufacturing process is the key to achieving ‘right first time’ results consistently. Our procedures are meticulously monitored and continuously refined, aligning with the stringent standards of our ISO9001:2015 certification.

Our process encompasses the transformation of a bare PCB into a fully populated and rigorously tested PCB assembly, ready for delivery to our clients. This thorough approach ensures unmatched quality and reliability in every product we manufacture.

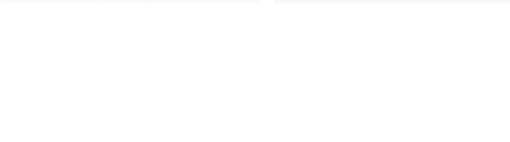

From Bare PCB to Populated Board

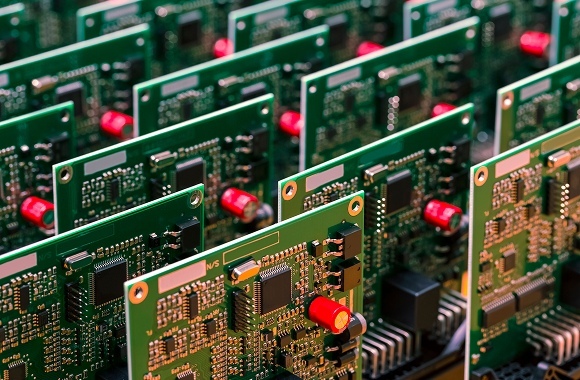

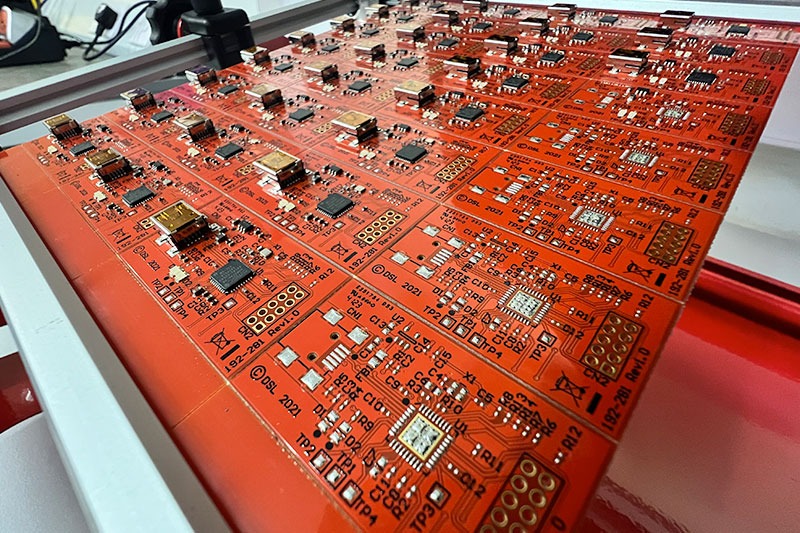

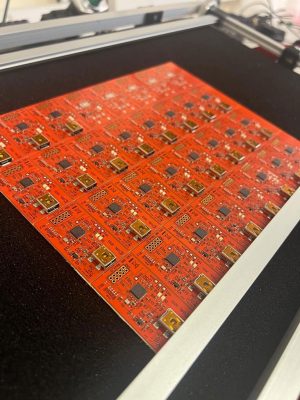

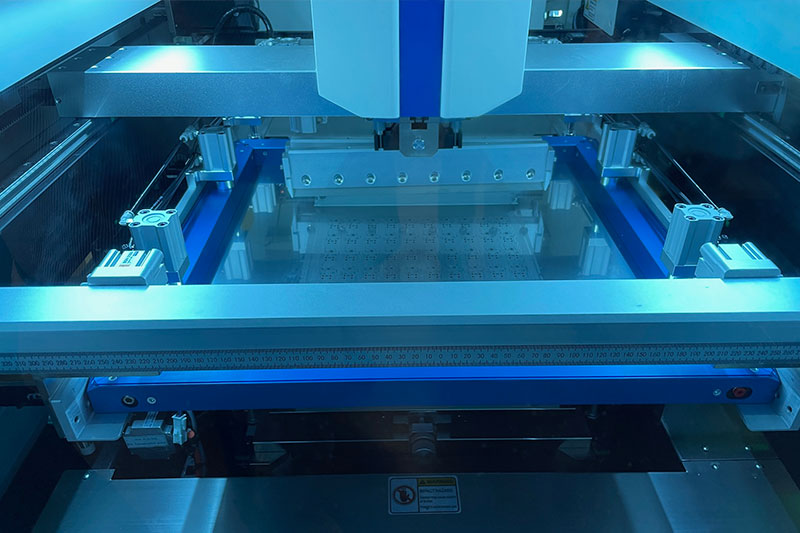

PCB assembly at DSL begins with a bare PCB, sourced from trusted suppliers to ensure authenticity and quality. Electronic components, delivered in reels and trays, are meticulously loaded into our dual in-line Pick and Place machines. The first step in the assembly process involves applying solder paste to the thousands of pads on the bare PCB.

Conveyors then smoothly transition the PCB into the Pick and Place machines. Here, a myriad of components, ranging from tens to thousands, are swiftly and accurately picked, scanned, and placed onto the PCB with sub-millimetre precision. Once the placement is complete, the PCB is conveyed into our reflow oven. It moves through various temperature-controlled zones, where the solder is heated and cooled precisely, ensuring that each solder joint is perfectly adhered.

This meticulous process highlights DSL’s commitment to precision and quality in every step of the Surface Mount Technology manufacturing.

From Bare PCB to Populated Board

PCB assembly at DSL begins with a bare PCB, sourced from trusted suppliers to ensure authenticity and quality. Electronic components, delivered in reels and trays, are meticulously loaded into our dual in-line Pick and Place machines. The first step in the assembly process involves applying solder paste to the thousands of pads on the bare PCB.

Conveyors then smoothly transition the PCB into the Pick and Place machines. Here, a myriad of components, ranging from tens to thousands, are swiftly and accurately picked, scanned, and placed onto the PCB with sub-millimetre precision. Once the placement is complete, the PCB is conveyed into our reflow oven. It moves through various temperature-controlled zones, where the solder is heated and cooled precisely, ensuring that each solder joint is perfectly adhered.

This meticulous process highlights DSL’s commitment to precision and quality in every step of the Surface Mount Technology manufacturing.

Contact us today

Speak to one of our knowledgeable and experienced team.

Why Clients Choose DSL

DSL’s exceptional client feedback stems from our commitment to quality, innovation, and tailored customer service. Our team’s expertise and dedication ensure reliable electronic manufacturing solutions that meet specific client needs. We prioritise effective communication and support, fostering lasting relationships by delivering consistently high-quality and timely products.

Quality and Innovation

Customised Solutions

Reliable Communication

Customised Solutions

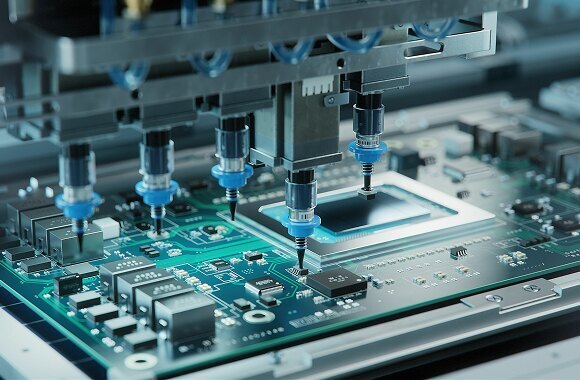

Completing the PCB Assembly

Once the PCB is populated with SMT components, it’s time for the meticulous addition of through-hole components. This step is carried out by skilled operators who carefully remove the PCB assembly from the SMT line. These professionals bring their expertise to the table, soldering each through-hole component by hand with precision and care.

This phase is crucial for components that require a stronger physical connection to the board, ensuring the assembly’s durability and reliability. The combination of automated SMT processes and manual through-hole assembly underscores DSL’s commitment to a comprehensive and detail-oriented manufacturing approach, ensuring the highest quality in every PCB assembly.

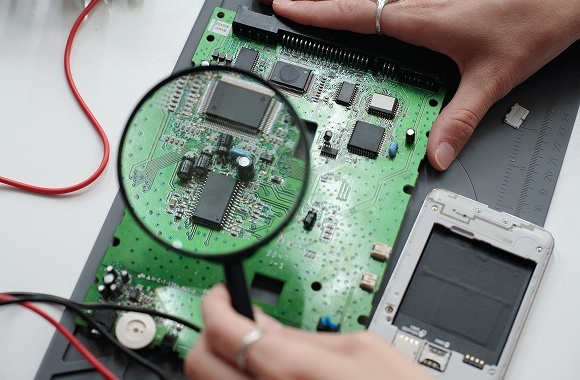

Ensuring Perfection with Advanced Testing

After the assembly is complete, the critical testing phase begins. DSL employs state-of-the-art 3D automated optical inspection (AOI) equipment for this purpose. The AOI machine captures thousands of high-definition images from various angles, comparing each detail against a known good baseline model. If it detects even the slightest anomaly in a solder joint, it signals for further inspection.

Only after the 3D AOI machine confirms the assembly’s integrity do we proceed to connectivity and functional testing. These rigorous testing procedures are essential to affirm that the PCB assembly functions flawlessly, living up to DSL’s high standards of perfection in every product we deliver.

why choose Dsl

With over 30 years of expertise in electronic design and manufacturing, DSL deeply understands the nuances that differentiate an average Contract Electronics Manufacturer (CEM) from an exceptional one.

Our commitment to excellence is evident in our extended warranties, flexible delivery options, and the presence of on-site experts who are not just adept at designing PCBs but are masters of their craft.

35+ Years of Experience

We’ve been around since Microsoft first released Windows – technology has changed but the core principles of robust electronic design and manufacturing remain the same.

5 Year Warranty

This underpins everything we do as a company, from robust processes, the latest equipment to long term reliable products.

3D AOI

We inspect each PCB assembly with thousands of high definition photos from every conceivable angle to compare to a known good master, all at the push of a button!

Made in Britain

We believe in British manufacturing and so do our clients, the local support, control and quality is tantamount to everything we believe in.

Final Steps and Optional Box Build Service

Once we’ve confirmed the flawless construction of the PCB assembly, the next steps can vary based on client needs. For some, this is the final stage; we carefully package the PCB assembly and store it, ready for shipment.

However, many of our clients take advantage of our comprehensive box build service. This additional phase involves the mechanical assembly of the PCB into an enclosure or similar structure. Utilising this service helps clients reduce their assembly workload and streamlines the process on their end. Whether it’s simply delivering the perfect PCB assembly or providing further assembly services, DSL is equipped to meet a diverse range of client requirements, ensuring a tailored and efficient solution from start to finish.