Did you know that reducing failure rate can save your business money? In many industrial situations, even a small increase in the failure rate can lead to huge losses in terms of time and money. So any reduction in the failure rate and the resultant costs can increase efficiency and profitability.This is why it’s so important for organisations to invest in technology that can help reduce failure rates. In this blog post, we will discuss how industrial PCs can help reduce failures, improve efficiency and increase cost savings in your organisation.

Did you know that reducing failure rate can save your business money? In many industrial situations, even a small increase in the failure rate can lead to huge losses in terms of time and money. So any reduction in the failure rate and the resultant costs can increase efficiency and profitability.This is why it’s so important for organisations to invest in technology that can help reduce failure rates. In this blog post, we will discuss how industrial PCs can help reduce failures, improve efficiency and increase cost savings in your organisation.

Less Downtime

Industrial PCs are designed to withstand the rigours of industrial environments. They are built for 24/365 operation and can handle extreme temperatures, vibration, and dust. They are ideal for use in factories, warehouses, and other industrial settings that ordinary PCs wouldn’t be able to cope with.

As a result, one of the biggest benefits of using an industrial PC is that it can help reduce downtime. Downtime is expensive, and it can lead to a loss of productivity. When a computer crashes, it can take minutes or even hours to restart. This downtime can be costly for businesses.

Industrial PCs are specifically built to withstand tough conditions and provide reliable performance in demanding environments.

Here are some of the reasons why industrial PCs have less downtime:

- They’re designed for round the clock operation. Unlike consumer PCs that are designed for intermittent use, industrial PCs are built for continuous operation. This means they can run for longer periods of time without overheating or needing a restart.

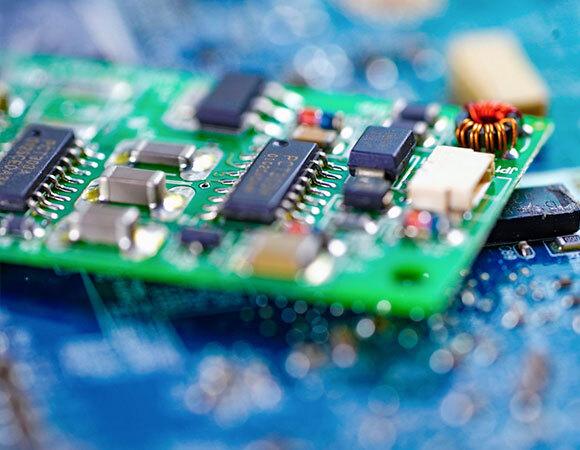

- They’re made with high-quality components. Industrial PCs use higher-quality components than consumer PCs, which makes them more durable and less likely to fail. They typically have large-capacity hard drives and error-correcting memory that make them more resistant to data loss.

- They have better cooling systems. Industrial PCs often have more robust cooling systems than consumer PCs, which helps to prevent overheating and extends the life of the components.

- They’re regularly maintained. Due to their critical role in industrial applications, industrial PCs are typically given more attention when it comes to maintenance and repairs. This helps to prevent problems before they cause downtime.

- They often come with redundant components and backup power supplies that further reduce the risk of downtime.

Higher Accuracy

More accurate sensors, processors and control systems found in industrial PCs are resulting in reduced failure rates for machines and processes. These advanced capabilities are allowing organisations to avoid or mitigate several types of manufacturing and business risks.

More accurate sensors, processors and control systems found in industrial PCs are resulting in reduced failure rates for machines and processes. These advanced capabilities are allowing organisations to avoid or mitigate several types of manufacturing and business risks.

One area where industrial PCs deliver greater accuracy is in temperature measurement. In food and beverage processing, for example, precise and stable temperatures are crucial to meeting hygiene standards and ensuring product quality.

Temperature sensors in industrial PCs can measure within a tenth of a degree, making it possible to manage process temperatures with greater precision. As a result, there is less risk of spoilage and contamination, and products are more likely to meet quality standards.

Enhanced Data Analysis

Another way that industrial PCs reduce risk is by providing better visibility into machine data. By collecting data from multiple sources across the factory floor, industrial PCs can give operators a more complete picture of what is happening in the production process. This allows problems to be more accurately predicted as well as detected sooner, before they result in production delays or downtime.

Additionally, the data collected by industrial PCs can be used to gain control by improving preventive maintenance programmes, further reducing the likelihood of unplanned downtime.

In today’s competitive marketplaces, the ability to reduce risks associated with manufacturing is essential for any organisation that wants to maintain a long-term competitive advantage. Industrial PCs are playing an increasingly important role in helping businesses achieve this goal.

Companies can also reduce the failure rate of their products and save money in the following ways:

- Improve the quality of products. This can be done by using better materials, better design, and better manufacturing processes.

- Improve the maintenance and repair procedures. This includes making it easier for customers to return defective products and ensures that repairs are carried out quickly and efficiently.

- Reducing the number of warranty claims. This can be done by providing better customer support and making it easier for customers to obtain replacement parts or repairs.

Collecting data in these different areas and analysing how they can be improved will lead to reduced failure rates in each, and industrial PCs play a vital role in this regard. In addition to their enhanced processing ability, they can also be customised with bespoke programmes to use data to get the best out of an organisation.

As the world becomes more and more digitised, the role of industrial PCs will only become more important with regard to cost savings. They are the backbone of many industries, and they will continue to help organisations to reduce downtime, improve quality and accuracy, and stay competitive.

Looking to establish a seamless partnership with DSL Electronics? Take the first step by completing our credit application. Our streamlined process ensures you get the credit terms you need to keep your projects moving forward.