Box Build Assembly

Box Build Assembly and Installation Solutions

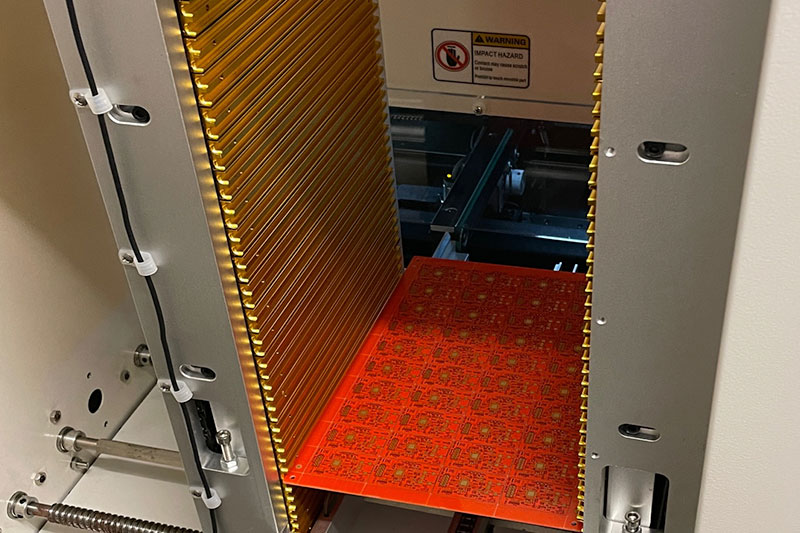

After producing your PCB assembly, DSL’s Box Build Assembly service steps in to provide complete mechanical installation into an enclosure.

This service is ideal for clients without internal assembly resources, encompassing all internal cabling, software installation, and functional testing. Our Box Build service ensures every process is meticulously handled, delivering your product fully assembled and ready for use.

The Versatility of Box Build Services

Box Build services cater to a wide array of requirements, ranging from the simple task of placing a expert PCB assembly into an enclosure to more complex operations. At its most intricate, Box Build can involve installing firmware/software, crafting and fitting cabling, inspection, licensing, labelling, serialisation, connectivity and burn-in testing, and comprehensive functional testing.

Determining the extent of external versus in-house assembly is a nuanced decision, balancing the optimal use of internal and external resources. While some cases are clear-cut, like a CEM pre-assembling an aircraft’s black box, others require careful consideration to decide the most efficient and logical approach.

At DSL, we help our clients navigate these decisions, offering tailored Box Build solutions to meet their specific needs and ensure the best possible outcome for their projects.

Contact us today

Speak to one of our knowledgeable and experienced team.

Why Clients Choose DSL

DSL’s exceptional client feedback stems from our commitment to quality, innovation, and tailored customer service. Our team’s expertise and dedication ensure reliable electronic manufacturing solutions that meet specific client needs. We prioritise effective communication and support, fostering lasting relationships by delivering consistently high-quality and timely products.

Quality and Innovation

Customised Solutions

Reliable Communication

Customised Solutions

Full Box Build/Assembly

For clients without internal production resources, DSL offers the ideal solution: a fully assembled, tested, and boxed product ready for immediate shipment to their customers.

We manage the entire process, from the initial assembly to the final packaging, ensuring that each product meets the highest standards of quality and functionality. Our services also include custom packaging and serialisation tailored to client specifications.

This comprehensive approach allows our clients to streamline their operations and focus on their core business, while we handle the complexities of product assembly and preparation, delivering a turnkey solution that is efficient, reliable, and ready for market.

Partial Box Build/Assembly

DSL also caters to clients with internal production capabilities but who still benefit from partial box build services. In scenarios where it’s more time-efficient or tool-intensive for a client to handle certain aspects of assembly, such as pre-installing firmware/software or basic cabling, DSL steps in to assist.

Our flexible approach ensures that each client receives their manufactured product in a state that best suits their needs, whether that involves partial assembly or additional pre-installation processes.

By partnering with DSL, clients can leverage our expertise and facilities to optimise their production workflow, ensuring that they receive their products in the most efficient and practical manner.

Intelligent Box Build with Expert Oversight

At DSL, our assembly process goes beyond simply following instructions. Our team of skilled engineers is deeply involved in understanding how your product functions, ensuring a thoughtful and informed approach to assembly. This expertise is crucial when dealing with the inevitable quirks and challenges that arise in electronic manufacturing.

Our engineers are always on hand to swiftly address and resolve any issues, ensuring a seamless process. This proactive approach minimizes the risk of delays and impacts on delivery, providing our clients with the assurance that their products are not just assembled, but intelligently crafted with expert care and attention to detail.