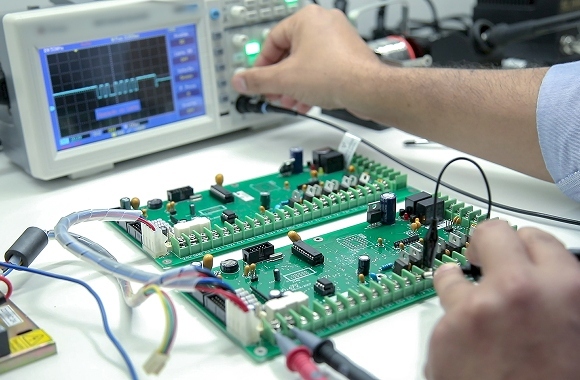

Functional Testing in PCB Assembly

The Importance of Functional Testing

- Powers up and operates correctly.

- Interfaces properly with other hardware or software.

- Detects potential programming or component failures that visual inspection cannot identify.

For example, if a board contains a pre-programmed device, DSL has no way of verifying that it was programmed correctly unless functional testing is available. Similarly, a visually perfect but defective component may pass inspection but fail in actual use.

To mitigate these risks, DSL actively encourages clients to work with us in developing test procedures that ensure functional verification. Even in cases where the cost of testing may seem prohibitive—such as for simple or low-value boards—investing in testing infrastructure can lead to significant long-term savings by reducing failures in the field.

Why Clients Choose DSL

DSL’s exceptional client feedback stems from our commitment to quality, innovation, and tailored customer service. Our team’s expertise and dedication ensure reliable electronic manufacturing solutions that meet specific client needs. We prioritise effective communication and support, fostering lasting relationships by delivering consistently high-quality and timely products.

Quality and Innovation

Customised Solutions

Reliable Communication

Customised Solutions

Contact us today

Speak to one of our knowledgeable and experienced team.

Custom Testing Solutions

- Develop bespoke functional test jigs tailored to specific PCBAs.

- Automate test procedures to improve efficiency.

- Provide cost-effective solutions for large-scale production.

Why Testing Matters

Functional testing helps ensure that every board shipped from DSL meets performance expectations, delivering peace of mind to our clients. By thoroughly verifying each PCBA, we reduce the likelihood of malfunctions, ensuring that every unit functions as expected in real-world applications.

A rigorous testing process not only enhances reliability but also significantly reduces the risk of costly rework, warranty claims, and field failures. Catching potential defects early in the process prevents expensive recalls and avoids reputational damage, safeguarding the integrity of your product. Comprehensive functional testing ensures that end-users receive products that work seamlessly right out of the box, reinforcing customer trust and satisfaction.

Maintaining Manufacturing Standards

By prioritising functional testing, DSL helps clients maintain high production standards while mitigating risks associated with undetected defects. Our approach to quality assurance makes testing a crucial step in the PCB assembly process, providing long-term value by ensuring operational reliability and reducing post-production challenges.

DSL is committed to delivering functionally flawless PCB assemblies. By working together to develop testing solutions, we help ensure that your product works perfectly—right out of the box. Contact us today to discuss testing strategies that align with your production needs and quality standards.