Inspection in Electronics Manufacturing

At DSL, inspection is a critical part of our PCB assembly process, ensuring that every unit meets the highest quality standards. We utilise a combination of automated and manual inspection techniques to identify and resolve potential defects, guaranteeing that our clients receive flawless, high-performance products.

There are two primary methods of PCB inspection: human inspection and machine inspection. Many manufacturers, including DSL, employ a hybrid approach that leverages the strengths of both methods to achieve optimal quality control.

Why Clients Choose DSL

DSL’s exceptional client feedback stems from our commitment to quality, innovation, and tailored customer service. Our team’s expertise and dedication ensure reliable electronic manufacturing solutions that meet specific client needs. We prioritise effective communication and support, fostering lasting relationships by delivering consistently high-quality and timely products.

Quality and Innovation

Customised Solutions

Reliable Communication

Customised Solutions

Contact us today

Speak to one of our knowledgeable and experienced team.

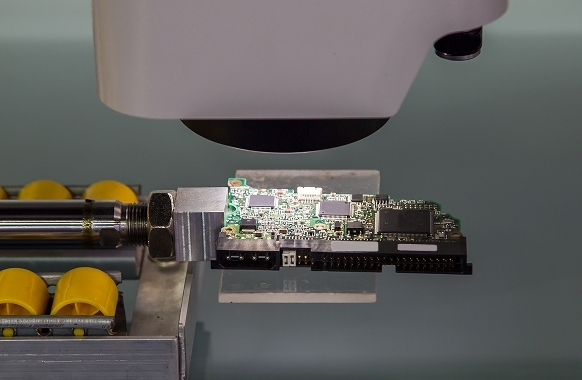

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) systems use high-resolution cameras to capture hundreds of images of an assembled PCB. These images are compared to a “known good” board to detect potential quality issues. If anomalies are found, they are flagged for further examination by a human operator.

Unlike traditional 2D AOI, modern 3D AOI systems provide depth perception, allowing for more comprehensive inspections from multiple angles. This helps identify solder joint inconsistencies, lifted leads, and misaligned components that 2D systems might miss.

AOI is particularly effective for inspecting surface-mount components placed by automated machinery, where precision and consistency are essential.

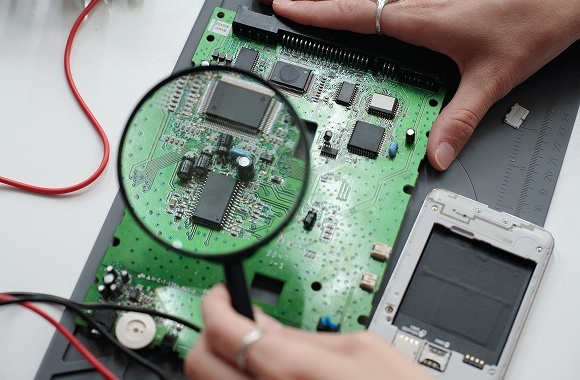

The Role of Human Inspection

- Soldering quality of through-hole components

- Alignment and placement of connectors, switches, and mechanical parts

- Overall board appearance and structural integrity

DSL’s Hybrid Inspection Model

- Identify and correct defects early in the production process.

- Reduce the risk of faulty assemblies reaching the final stage.

- Maintain consistency across all production runs.

Rigorous inspection processes improve product reliability, minimise failures, and enhance long-term performance. By ensuring that all defects are identified and corrected before shipping, DSL delivers high-quality PCB assemblies that meet the most demanding industry standards.

With cutting-edge AOI technology and skilled IPC-A-610-certified inspectors, DSL guarantees the highest level of quality control.