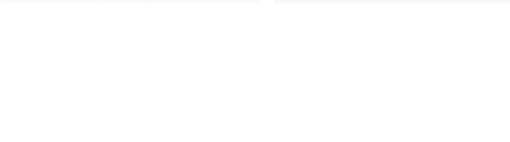

Kitting for Manufacture

The kitting phase is a crucial step in the PCB assembly process, ensuring all necessary components are procured, verified, and ready for production. At DSL, we meticulously manage this stage to prevent delays, control costs, and guarantee that each part meets the required specifications.

Kitting involves purchasing each component that makes up the PCB assembly, including the bare PCB itself. In an industry where lead times and pricing can fluctuate rapidly, this process is often more complex than it appears. The goal of this phase is to ensure all components arrive on time and in the correct specifications, allowing the assembly to proceed smoothly.

Why Clients Choose DSL

DSL’s exceptional client feedback stems from our commitment to quality, innovation, and tailored customer service. Our team’s expertise and dedication ensure reliable electronic manufacturing solutions that meet specific client needs. We prioritise effective communication and support, fostering lasting relationships by delivering consistently high-quality and timely products.

Quality and Innovation

Customised Solutions

Reliable Communication

Customised Solutions

Contact us today

Speak to one of our knowledgeable and experienced team.

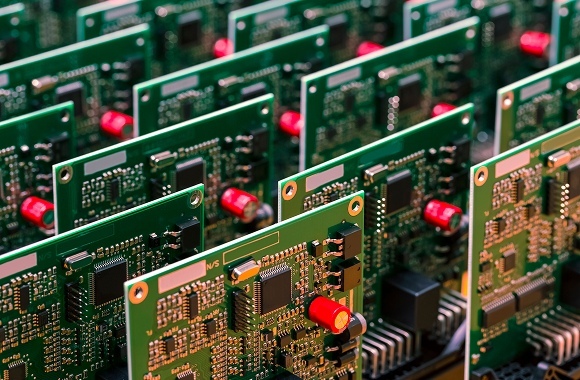

Managing Lead Times and Costs

One of the biggest challenges in kitting is dealing with component availability. Our experienced buyers work diligently to source all necessary components while keeping costs under control. They ensure that every part is delivered within a timeframe that allows for seamless assembly, avoiding delays and unexpected cost increases.

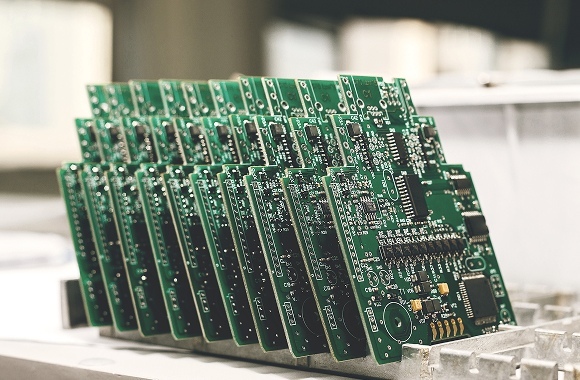

The bill of materials (BOM) often contains hundreds of individual components, each with its own specifications that must be adhered to precisely. These include:

- Electronic Components: Resistors, capacitors, ICs, and other critical elements.

- Bare PCB: The foundational circuit board that houses all components.

- Specialty Parts: Any custom or application-specific components required for functionality.

Validation and Preparation

- Every component meets the required specifications.

- No incorrect or defective parts are included.

- Quantities match the build requirements.

Why Kitting Matters

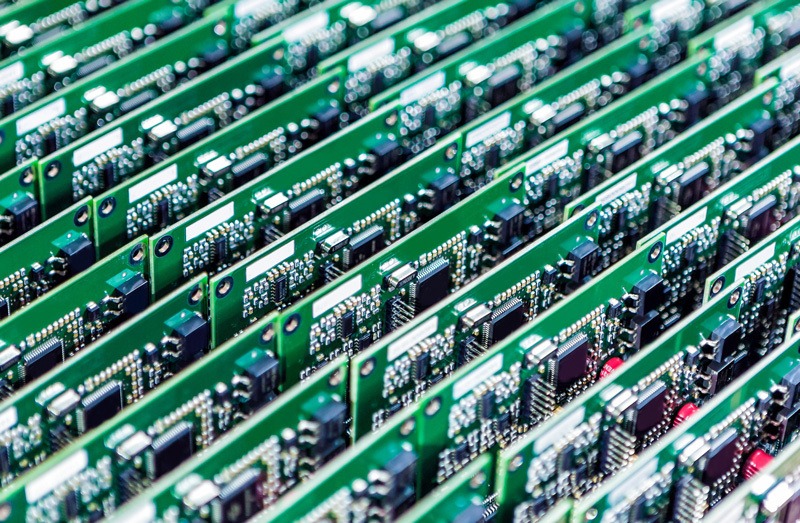

Partner with DSL for Reliable Kitting Solutions

With our expertise in procurement and supply chain management, DSL provides a seamless kitting process that guarantees accuracy, efficiency, and cost-effectiveness. By managing component sourcing, validation, and preparation, we help clients avoid common pitfalls and ensure their PCB assembly is set up for success.

Get in touch with DSL today to discuss your kitting needs and discover how our meticulous approach can enhance your electronic manufacturing process.